Raw materials are the basic, unprocessed substances used to produce goods, products, or finished items. These materials are usually extracted from nature or harvested in their natural state and are then processed or manufactured into final products.

Eco Friendly Raw Materials

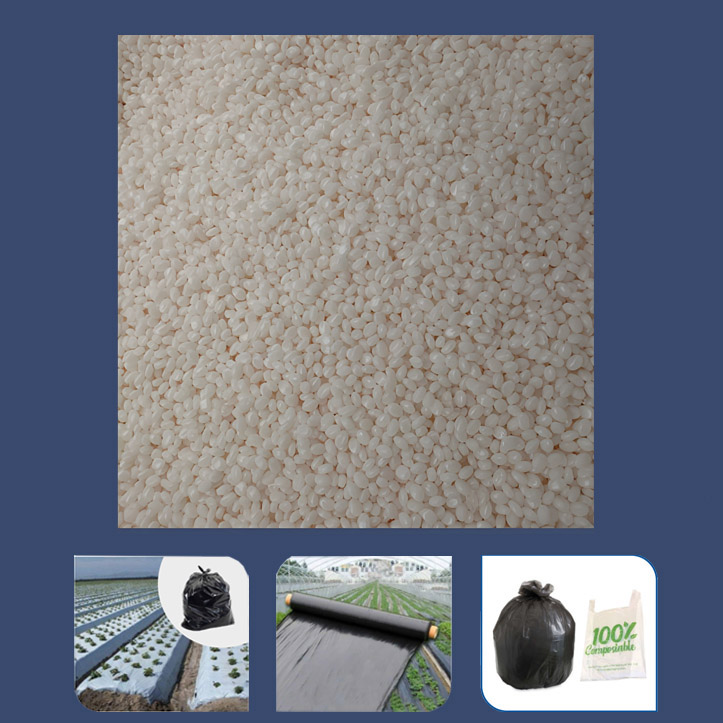

Bio Filler Compound

Compostable bio fillers are eco-friendly additives blended into bioplastics to enhance functionality and reduce costs. They consist of natural or biodegradable components such as mineral powders (e.g., calcium carbonate, talc) or plant-derived materials (e.g., starch, agricultural residues), combined with compostable polymers like PLA or PBAT

Compostable Compound For Injection Moulding

Compostable bio filler compounds contains an Inorganic calcium carbonate and aliphatic biodegradable PBAT resin. It is in organic filler concentrate masterbatch. It does not contain any petroleum base polymer or additives.

Key Raw Materials

- PLA (Polylactic Acid) – Derived from corn starch or sugarcane, offering stiffness and clarity.

- PBAT (Polybutylene Adipate Terephthalate) – Flexible and tough, often blended with PLA.

- Starch-based Polymers – Enhance biodegradability and cost efficiency.

- Cellulose & Natural Fibers – Improve strength and thermal stability.

Features & Benefits

- 100% Compostable

- Injection Moulding Friendly

- Excellent Mechanical Properties

- Safe & Sustainable

- Versatile

Masterbatches

United Biopolymers offers a wide range of masterbatches based on various carrier polymers such as PLA, PBAT & other polymers and are produced in accordance with EN 13432

Product Features of our masterbatches

- Wide range of applications

- Excellent Dispersion

- Free of heavy metals and phthalates

United Biopolymers Carbon Black Masterbatch

In agriculture applications, mulch films are used to cover the soil to suppress weeds and to promote the crops growth. To optimize growth and harvest of the crops and to protect the film against UV radiation, the flim compound can be colored into black with our carbon black masterbatch during the converting process

- Masterbatch based on biodegradable carrier with high loading level of carbon black pigment

- Produced in accordance with EN 13432

United Biopolymers Additive Masterbatch

We manufacture additive masterbatches with biodegradable carrier materials which are paired with corresponding active ingredients. We offer, for example

- Functional Masterbatches

- Anti Block Masterbatches

- Blowing agent Masterbatches